- Additive Manufacturing/3D Printing

Safe filtration during powder bed fusion--In the field of additive manufacturing, the metallic raw materials are in most cases highly reactive and place maximum demands on sustainable safe handling. The reactive particle loads must therefore not enter the atmosphere of the production room. However, condensate and dust should not remain in the building chamber either as the quality of a build job in almost all additive manufacturing processes is directly related to the degree of embedded contamination and foreign particles.

The optimum solution is offered by the realization of pure surface filtration with the our Sinter-Plate Filters in combination with safe, consistent passivation as well as integration into the inert gas circuit of the systems.

- Automotive Industry

--The automotive industry has never been so competitive, and manufacturers face more challenges than ever. Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly efficient filtration is essential in the Automotive Industry. Our Sinter-Plate Filters base on pure surface filtration and combine very high separation efficiency with unparalleled durability. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

--The automotive industry has never been so competitive, and manufacturers face more challenges than ever. Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly efficient filtration is essential in the Automotive Industry. Our Sinter-Plate Filters base on pure surface filtration and combine very high separation efficiency with unparalleled durability. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

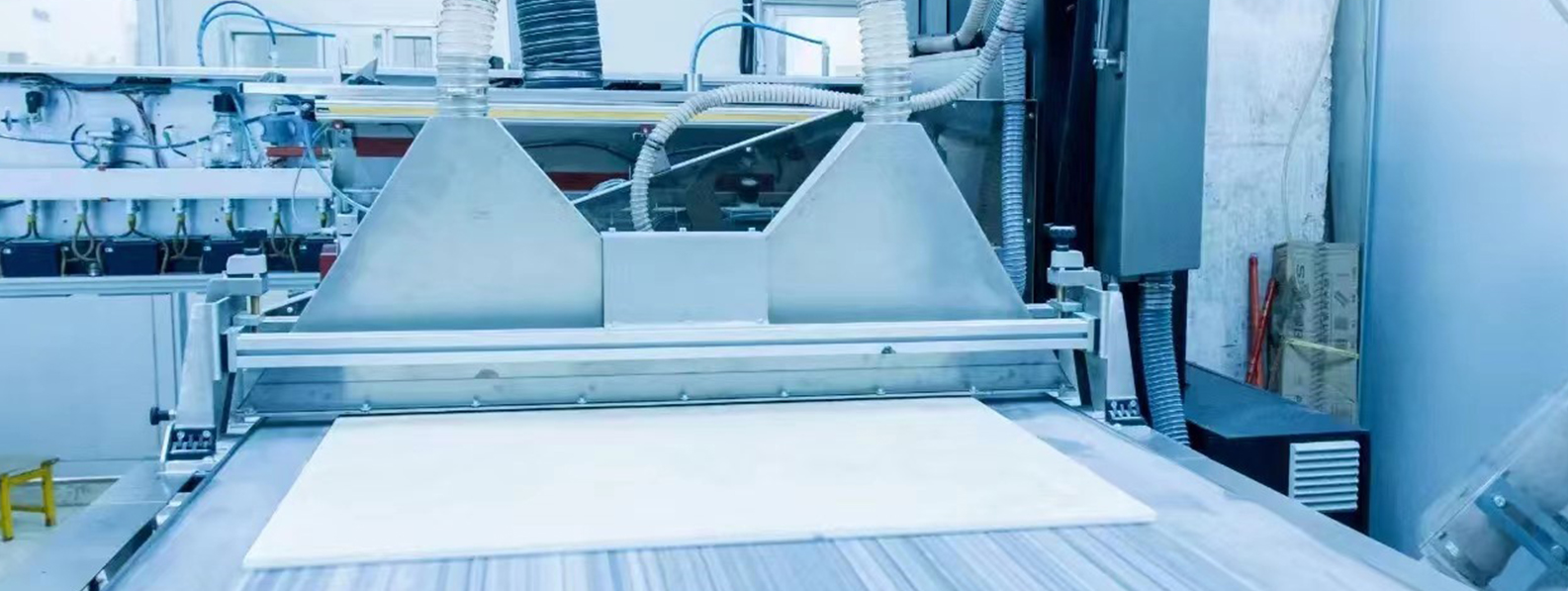

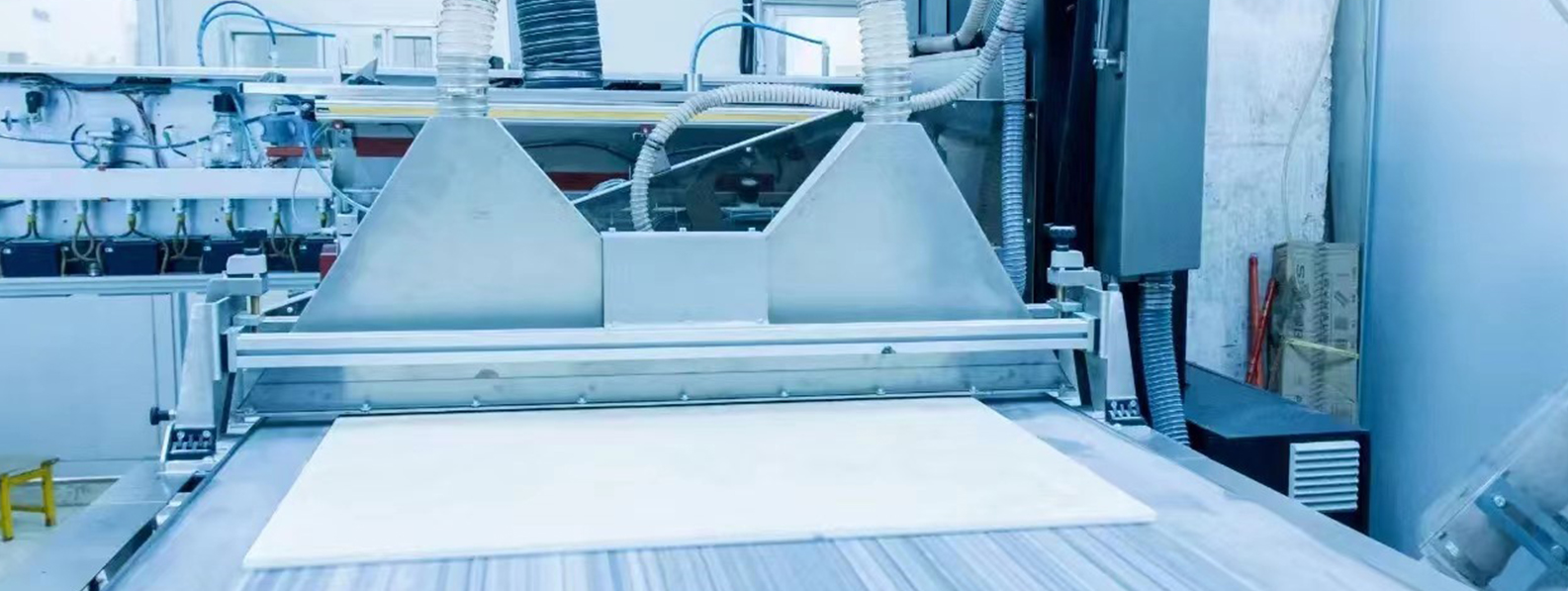

- Ceramics Production

--Safe separation of fine quartz dust is necessary during ceramics production processes

--Safe separation of fine quartz dust is necessary during ceramics production processes

Our Sinter-Plate Filter bases on pure surface filtration. It sustainably protects man and machine from harmful production emissions, reliably separates even the finest dust fractions, and directly increases your productivity.

- Chemical Industry

--Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly performing dust collection equipment is a must. in chemical production processes in which bulk materials, powders or other particulate educts or products play a role. Our filter systems meet the highest requirements in terms of contamination-free operation, durability and safe handling. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

--Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly performing dust collection equipment is a must. in chemical production processes in which bulk materials, powders or other particulate educts or products play a role. Our filter systems meet the highest requirements in terms of contamination-free operation, durability and safe handling. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

- Food Industry

--Food processing is a dusty business. Dust control for food processing is important from both a food safety perspective and a worker health and safety perspective. Uncontrolled food dusts create many different types of problems, including sanitation concerns, cross-contamination, microbial contamination, health issues for workers and slip-and-fall hazards.

- Laser Processing

Safe extraction of fine metal dust and fumes

--The laser processing of metals by cutting, welding, marking or structuring generates fumes that consist of a large number of toxic aerosols and gases as well as fine dusts of the respirable fraction. These cause significant health hazards for the operating personnel and, last but not least, damage and contaminate the laser optics, aggregates and the product to be processed. This results in high standard for the filter technology in this area.

Our filter systems work on the principle of pure surface filtration. They have been proven to reliably separate even the finest dust fractions. Combined with an effective fume capturing, this sustainably protects man, machine and the environment from harmful emissions.

- Mechanical Metal Working

--Dust removal of lead, zinc, cadmium or other heavy metals, including their compounds. --Highly efficient filtration is essential in the mechanical processing of metals and the resulting emissions. Especially, the occurring fine particulates pose increased risks for the health of the operating personnel. In addition, the contamination of processing machines, workplaces and the product to be processed causes considerable impairments and potentially high costs.

--Dust removal of lead, zinc, cadmium or other heavy metals, including their compounds. --Highly efficient filtration is essential in the mechanical processing of metals and the resulting emissions. Especially, the occurring fine particulates pose increased risks for the health of the operating personnel. In addition, the contamination of processing machines, workplaces and the product to be processed causes considerable impairments and potentially high costs.

Our Sinter-Plate Filters base on pure surface filtration and combine very high separation efficiency with unparalleled durability. It thus meets the high demands on the filter technology used in this field and sets equal standards compared to conventional filter media. In combination with an effective dust collection, humans, machine and the surroundings are protected sustainably from harmful emissions.

- Mineral Industry

Dust collection for ore crushing, screening and transportation.

Dust collection for ore crushing, screening and transportation.--The awareness for fine quartz dust has grown considerably in the mineral processing industry in recent years. Stricter standards and limit values are increasing the demands on filtration efficiency and safety.

Our Sinter-Plate Filter bases on pure surface filtration. It sustainably protects man and machine from harmful production emissions, reliably separates even the finest dust fractions, and directly increases your productivity.

- Pharmaceutical Industry

--Dust removal of granulator, tablet machine, coating machine, and pretreatment of traditional Chinese Medicine

--Particulate emissions are generated throughout the entire process chain of pharmaceutical solids production. These emissions must be kept free of hazards in the containment, handled without contamination during discharge, and separated almost absolutely in the filtration process. Our filter systems meet the highest requirements in terms of contamination-free operation and safe handling. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

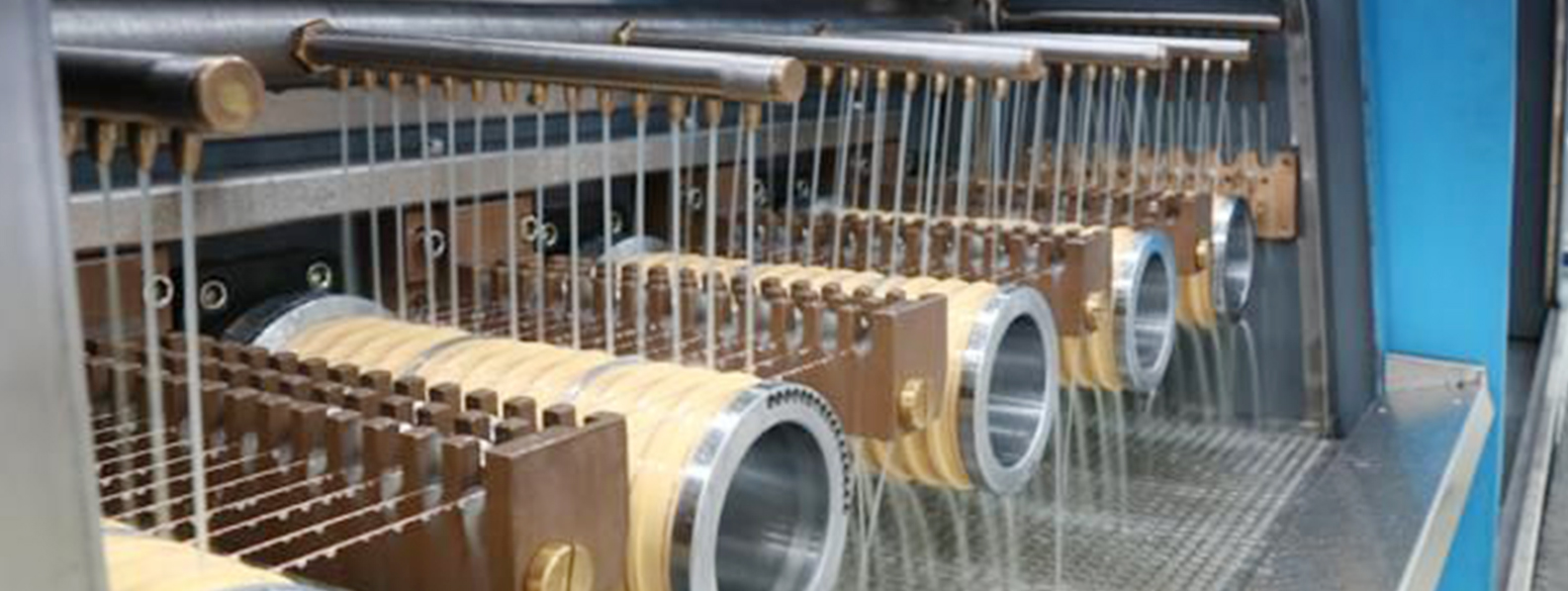

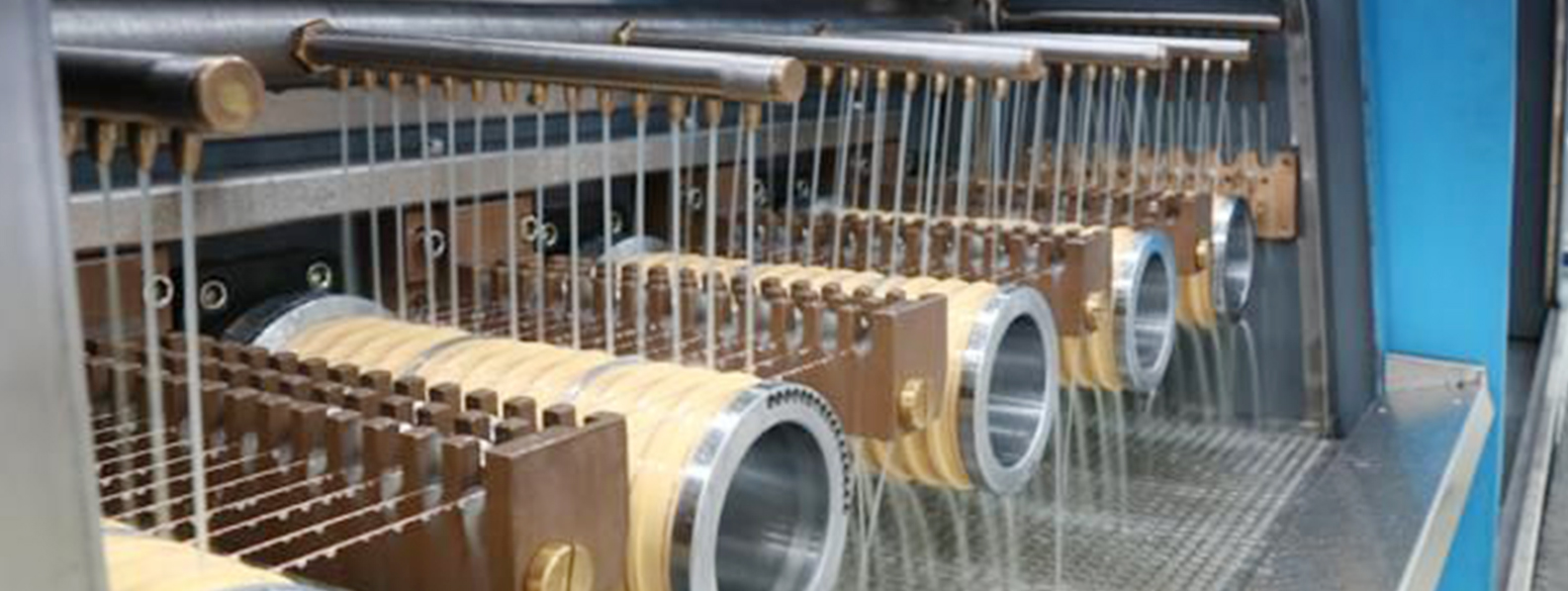

- Wire Drawing

--The process of drawing metal wires generates harmful production emissions such as metal dust, scale and drawing lubricant abrasions, which must be reliably extracted to sustainably protect man, machine and the environment.

--The process of drawing metal wires generates harmful production emissions such as metal dust, scale and drawing lubricant abrasions, which must be reliably extracted to sustainably protect man, machine and the environment.

Our filter systems work on the principle of pure surface filtration. They have been proven to reliably separate even the finest dust fractions with a residual dust content of < 0.1 mg/m³.

--The automotive industry has never been so competitive, and manufacturers face more challenges than ever. Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly efficient filtration is essential in the Automotive Industry. Our Sinter-Plate Filters base on pure surface filtration and combine very high separation efficiency with unparalleled durability. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

--The automotive industry has never been so competitive, and manufacturers face more challenges than ever. Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly efficient filtration is essential in the Automotive Industry. Our Sinter-Plate Filters base on pure surface filtration and combine very high separation efficiency with unparalleled durability. Even the finest particle fractions are reliably separated on the basis of pure surface filtration. --Safe separation of fine quartz dust is necessary during ceramics production processes

--Safe separation of fine quartz dust is necessary during ceramics production processes --Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly performing dust collection equipment is a must. in chemical production processes in which bulk materials, powders or other particulate educts or products play a role. Our filter systems meet the highest requirements in terms of contamination-free operation, durability and safe handling. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

--Managing a factory floor today is more than just a matter of keeping the line moving. Air quality regulations and the need to maintain a safe and clean workplace require constant vigilance. Highly performing dust collection equipment is a must. in chemical production processes in which bulk materials, powders or other particulate educts or products play a role. Our filter systems meet the highest requirements in terms of contamination-free operation, durability and safe handling. Even the finest particle fractions are reliably separated on the basis of pure surface filtration.

--Dust removal of lead, zinc, cadmium or other heavy metals, including their compounds. --Highly efficient filtration is essential in the mechanical processing of metals and the resulting emissions. Especially, the occurring fine particulates pose increased risks for the health of the operating personnel. In addition, the contamination of processing machines, workplaces and the product to be processed causes considerable impairments and potentially high costs.

--Dust removal of lead, zinc, cadmium or other heavy metals, including their compounds. --Highly efficient filtration is essential in the mechanical processing of metals and the resulting emissions. Especially, the occurring fine particulates pose increased risks for the health of the operating personnel. In addition, the contamination of processing machines, workplaces and the product to be processed causes considerable impairments and potentially high costs. Dust collection for ore crushing, screening and transportation.

Dust collection for ore crushing, screening and transportation.

--The process of drawing metal wires generates harmful production emissions such as metal dust, scale and drawing lubricant abrasions, which must be reliably extracted to sustainably protect man, machine and the environment.

--The process of drawing metal wires generates harmful production emissions such as metal dust, scale and drawing lubricant abrasions, which must be reliably extracted to sustainably protect man, machine and the environment.